玻璃纤维贸易

2021年,袋鼠先生成为泰山玻璃纤维有限公司的澳洲经销商,主要为澳洲市场提供玻璃纤维毡布用纱、开模成型工艺用玻璃纤维和管道及贮罐成型工艺用玻璃纤维。

泰山玻璃纤维有限公司隶属于中国建材集团有限公司所辖中材科技股份有限公司(股票简称:中材科技,股票代码:002080)的全资子公司,是以玻璃纤维及制品的研发、生产、销售为主业的国有大型企业。1997年建成当时国内首条万吨无碱玻纤池窑拉丝生产线,填补国内空白。目前玻纤制品总产能达到百万吨级规模,为全球三大、中国两大玻璃纤维制造企业之一。

泰山玻纤在无碱玻纤大型池窑设计、窑炉纯氧燃烧技术、专用漏板设计等方面拥有国际先进的自主核心技术,公司拥有国家认定企业技术中心、省级重点实验室、博士后科研工作站等研发机构。公司实验室通过CNAS认证和GL认证,具备了开展对外检测和校准服务的资质。

泰山玻纤通过了ISO9001、汽车行业IATF16949质量管理体系认证、ISO14001环境管理体系、ISO45001职业健康与安全管理体系认证,产品通过了中国船级社、挪威船级社、英国劳氏船级社、印尼船级社的产品型式认可,美国FDA认证及德国GL认证等。泰山玻纤设立了CTG北美公司、南非公司等驻外公司及机构,与北美、中南美、欧洲、中东、亚太等70多个国家和地区的客户建立了长期稳定的合作关系。

泰山玻纤满莊新区自2012年4月开工建设,目前玻纤制品生产能力已达到75万吨/年,2015年被国家工信部列为国家首批玻璃纤维智能制造示范工厂,2016年入选国家智能制造应用新模式示范名单,成为玻纤行业智能化、信息化、自动化的示范工厂。

Fiberglass Trading

In 2021, MR KANGAROO became the Australian distributor of Taishan Fiberglass Inc.(CTG), mainly providing the Australian market with FIBERGLASS SOLUTIONS TO OPEN MOLDING, FIBERGLASS ROVING FOR MATS & FABRICS, FIBERGLASS SOLUTIONS TO PIPES & TANKS.

Taishan Fiberglass Inc.(CTG), is a wholly-owned subsidiary of Sinoma Science & Technology Co., Ltd. (Stock Code: SZ002080) under China National Building Material Group Co., Ltd.

Established in 1997 with the 1st E glass fiber furnace production line of 10,000mts/year in China, CTG has reached a manufacturing capacity of 800,000+ mts/year of diversified fiberglass products, and is one of world’s top 3 and China’s top 2 fiberglass manufacturers.

Equipped with world’s cutting-edge technologies of hyper fiberglass furnace design, Oxy-firing, specialty glassfiber busing design, etc. and leading research & development institutes such as China National Fiberglass R&D Center, Key Laboratory of Shandong Province, Post-doctoral Research Station, etc., CTG has been awarded with certificates of International Quality Management System (ISO9001), Environmental Management System (IS014001), Occupational Health & Safety Management System (GB/T28001) and our products are certified by DNV (Det Norske Veritas Type Approval Certificate, Norway), LR (Lloyd’s Register of Shipping, UK), FDA (Food & Drug Administration, US), KS (Korean Standard, Korea) GL (Germanischer Lloyd, Germany ) and China Classification Society (CCS, China), etc. CTG has established a global sales and service networks including the US (CTG International North America Inc.) and South Africa (Taishan Fiberglass Pty S.A) and our exports cover 70+ countries in Europe, North America, South America, Middle East, Asian-Pacific, etc.

After years of transformations, restructuring & upgrading since 2011, CTG has built a world`s leading Manzhuang new plant of 500,000mts/year capacity, with state-of-the-art automatic and intelligent equipment & facilities. It was listed in 2015 among ” The Intelligent Manufacturing Plants” by MIIT (China Ministry of Industry and Information Technology), which was the only model plant in China fiberglass industry.

喷射成型工艺用玻璃纤维产品

喷射纱

喷射纱采用硅烷型浸润剂表面处理,与不饱和聚酯树脂和乙烯基树脂有良好的兼容性,广泛应用于卫浴、造船等领域。

【产品特点】

- 线密度稳定

- 静电低、毛羽少

- 短切、分散性好

- 可用于机械手作业

手糊成型工艺用玻璃纤维产品

1、短切毡

玻璃纤维短切成一定长度后,无定向、均匀地降落在网带上,用聚酯粉未(或乳液)粘结剂使其粘结并卷取形成的片状制品。产品广泛应用于手糊成型工艺。

【产品特点】

- 单重均匀性好

- 浸透速度快、树脂消耗量低

- 硬度适中、敷模性好

2、方格布

由直接无捻粗纱经方格布织机织造而成,包括平纹布和斜纹布。产品广泛应用于手糊成型工艺。该产品能够双向增强,主要应用于 手糊工艺。和聚酯树脂、乙烯基 树脂和环氧树脂有良好的兼容性。

【产品特点】

- 制品强度高

- 单重均匀性好

- 浸透速度快

- 经纬向纱含量灵活设计

制毡工艺用玻璃纤维产品

制毡纱

连续板材用无碱玻璃纤维板材纱表面经过硅烷型浸润剂处理,与不饱和聚酯、乙烯基树脂有良好的兼容性,主要应用于各种短切毡、透明、半透明板材、波形瓦。

【产品特点】

- 静电低

- 铺层低

- 浸透速度快

- 分散均匀性好

- 主要使用于玻璃纤维、缝编毡

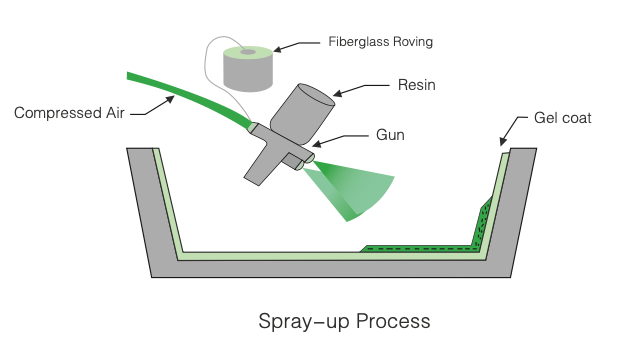

Fiberglass Product for Spray-up

Spray-up Roving

Spray up roving is coated with silane-based sizing, compatible with UP, VE resins and widely used to produce sanitary devices and marine vessels.

【Properties】

- Consistent linear density

- Low static & fuzz

- Good chop-ability and dispersion

- Applicable for robotic operation

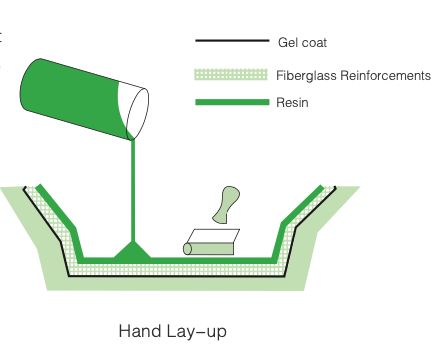

Fiberglass Product for Hand Lay-up

1. CSM

Chopped Strand Mat is made of chopped fiber in specified length, randomly & evenly distributed on conveyor, bonded together by polyester powder or emulsion binder and cut into certain widths and lengths after heat forming, It is mainly applicable for hand lay-up process.

【Properties】

- Even area weight

- Fast wet out and low resin consumption

- Medium rigidity and optimum molding performances

2. Woven Roving

Woven roving is made on looms by weaving direct roving into fabrics, including plain weave, twill weave, etc. It gives bi-directional (0°/90°) reinforcement, compatible with UP, VE & EP resin systems and is mainly used for hand lay-up process.

【Properties】

- High mechanical strength of finished products

- Even area weight

- Fast wet-out

- Flexible inputs of warp & weft

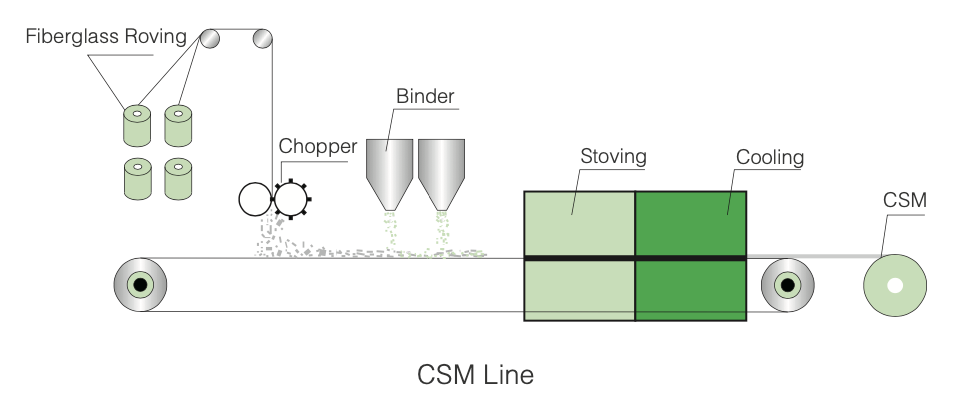

Roving for Mat Production

Roving for Mat

E glass roving for mat is coated with silane-based sizing, compatible with UP, VE resins and is widely used to produce CSM, transparent, translucent panels and corrugated sheets.

【Properties】

- Low static

- Low lay-down

- Fast wet-out

- Good dispersion

- Mainly used to produce CSM & Knitted Mat